Ecommerce Packaging Trends 2026 will change how brands pack, ship, and delight customers. As internet sales rise and consumers want greener, smarter boxes, the U.S. market will feel the change. Rising carrier costs and slimmer margins mean that stores have to reduce dimensional weight fees and minimize waste. With packaging growing at nearly 4.0% CAGR across the decade, U.S. demand for packaging should reach almost $224 billion in 2026.

According to polls, 72% of customers pick companies that send in packaging that is simple to open, neat, and clear. Because packaging accounts for almost 12% of logistics expenses, every decision impacts experience and profit. Thus, act now to capture savings and lift loyalty under the Ecommerce Packaging Trends 2026 wave.

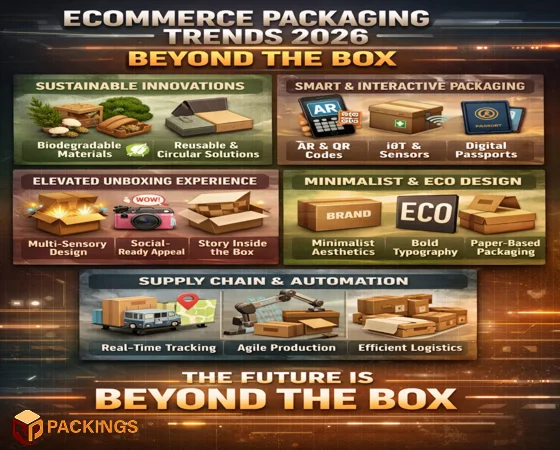

Ecommerce Packaging Trends 2026

This guide lists ten clear trends that will shape packaging choices in 2026.

1. Sustainable fibers and circular design

Brands will swap plastic for paper and molded pulp to cut waste and meet shopper demand. Many retailers set 50–70% recycled content goals for board and Tuck Top Mailer Boxes. Molded pulp cushions can cut plastic use by about 60% while keeping fragile items safe. Returnable ecommerce packaging solutions show single-use waste drops by roughly 20–30% in trials that run 6–12 months.

Use clear recycling marks and simple disassembly to help customers recycle more. These moves lower landfill waste and match new retailer rules. Test a single SKU with molded pulp and track returns, weight, and customer feedback for 90 days to see real savings.

- 50–70% recycled content targets for board and mailers

- Molded pulp cuts plastic use ~60% on tested SKUs

- Returnable pilots reduce single-use waste 20–30% in trials

2. Right-sizing to cut DIM fees

Fit boxes to products to lower carrier charges and fuel use. Automated box fitting can reduce void fill by 40% and cut dimensional (DIM) fees by 15–30% for many orders. Smaller boxes speed handling and lower damage rates by a few points. Use software to pick the best ecommerce box size and test common SKUs to find savings.

Pair right-sizing with lighter cushioning to keep items safe while trimming weight. Track average box volume and DIM fees weekly to spot trends. Many teams see payback in under six months when they reduce average box volume by 10–25%.

- Automated box fitting reduces void fill 40%

- DIM fee drops 15–30% after size optimization

- Average box volume cut 10–25% yields quick payback

3. Branded unboxing that lifts sales

Design the inside of the box to boost repeat buys and social shares. When brands assess premium presentation, branded inserts, tissue, and a clear note can boost repurchase intention by roughly 15–25% and increase average order value (AOV) by 5–12%. Encourage consumers to upload pictures in exchange for little discounts to help organic reach expand.

Use custom ecommerce boxes that show the logo and a clear return path to make returns easier and keep the brand front of mind. Track social mentions and repeat purchase rates for 90 days to measure impact. Small design changes often show measurable lift in conversion and loyalty.

- Repurchase intent up 15–25% with branded inserts

- AOV rises 5–12% for premium unboxing experiences

- User photos increase organic reach and referrals

4. Lightweight protection that saves weight

New cushioning options keep items safe while cutting weight and volume. Molded pulp and engineered paper pads reduce plastic use by about 50–70% and lower box weight by 5–20% depending on the product. Airless paper pads compress to save space and cut box volume by 10–25% on average.

Less weight lowers shipping fees and reduces carbon output per order. You can use ecommerce shipping boxes for this purpose. Test lightweight cushions on fragile SKUs and measure damage rates, returns, and carrier claims for 90 days. Many teams find that switching to paper-based protection reduces claims and improves sustainability scores without raising costs much.

- Molded pulp reduces plastic 50–70% on tested SKUs

- Box volume drops 10–25% with airless paper pads

- Weight falls 5–20% depending on product and cushion

5. Smart tracking and anti-loss tech

Add simple tags and codes to cut claims and speed delivery. Use QR codes on packing slips and RFID on pallets to track movement. Many warehouses report a 15–25% drop in lost items after adding basic tracking. Real-time tracking cuts claims by about 10–20% and improves customer trust.

Use low-cost QR stickers for small orders and RFID for high-value pallets. Track claim rates and delivery exceptions weekly to measure impact. Smart tags also help with returns and warranty checks, and they give you data to spot weak points in the supply chain. You can put them in your Corrugated Shipping Boxes as well.

- Lost items drop 15–25% with basic tracking tech

- Claims fall 10–20% after real-time visibility

- QR codes work for small orders; RFID helps pallets

6. Affordable custom options for small brands

Small brands can get a custom look without big inventory costs. On-demand printing cuts inventory by about 30–50% and lets teams test designs in short runs. Bulk pricing still lowers unit cost by 20–35% when volumes rise.

To expedite output and cut setup charges, use modular inserts and normal dielines. Low minimums and quick turnaround are available from many providers; therefore, companies can experiment with bespoke ecommerce packaging for a handful of SKUs. Decide which SKUs should be customized based on conversion lift, storage charges, and track unit cost. This approach keeps costs low while letting brands build a stronger unboxing story.

- On-demand printing cuts inventory 30–50%

- Bulk pricing lowers unit cost 20–35%

- Low minimums let brands test bespoke packaging

7. Returns-friendly design to cut handling time

Design packaging that makes returns quick and cheap. Use clear return labels and simple reseal options so customers can send items back without extra boxes. Reusable mailers and resealable bags can cut return handling time by 20–35% and lower labor costs. If you want affordable custom ecommerce packaging options, try this.

Clear instructions and pre-printed return slips reduce processing errors by about 10–15%. Track return handling time and cost per return to find the best design. Many teams cut return costs by testing a reusable mailer on high-return SKUs and measuring the change over three months.

- Return handling time drops 20–35% with reusable mailers

- Processing errors fall 10–15% with clear labels

- Measure cost per return monthly to track gains

8. Local sourcing to cut lead time and miles

Buy board and ecommerce packaging boxes from regional mills to cut transit time and emissions. Regional suppliers can shorten transit by 20–40% and reduce freight cost per unit. Local sourcing also lowers supply risk and speeds design changes. Many brands find that near-sourcing reduces lead time from weeks to days for common SKUs.

To reduce freight miles and foster circular systems, utilize local mills for recycled boards. Track lead time, freight cost, and carbon miles to compare local vs. distant suppliers. Slight changes in sourcing usually provide fast victories in sustainability and velocity.

- Transit time cuts 20–40% with regional suppliers

- Freight cost per unit falls when you source nearby

- Lead time drops from weeks to days for common SKUs

9. Data-driven packaging choices

Use tests and dashboards to pick the best materials and sizes. Run A/B tests on packaging to see which option lowers returns and lifts NPS. Many teams report a 4–8 point NPS gain after packaging improvements. Dashboards that track DIM fees, returns, and damage help teams cut waste spend by 10–15% in a year.

Use simple metrics like cost per order, damage rate, and return rate to guide choices. Set monthly goals and review the data to find the best mix of protection, weight, and brand impact. Data helps you scale what works and stop what does not.

- NPS can rise 4–8 points after packaging changes

- Waste spend falls 10–15% with dashboards and tests

- Track cost per order, damage rate, return rate monthly

10. Regulations, reporting, and transparency

Publish packaging targets and track progress to meet rules and shopper expectations. Many large retailers will require suppliers to report recycled content and end-of-life plans. Brands that publish targets gain trust and avoid fines or delisting. Supplier audits will rise to verify claims and ensure compliance.

Track recycled content, weight per order, and percent of reusable or recyclable White Cardboard Boxes Wholesale to meet buyer needs. Use clear labels and simple instructions to help customers recycle. Transparency helps you win shelf space and shopper trust while reducing risk from new rules.

- Publish recycled content and end-of-life plans to meet buyer needs

- Supplier audits increase to verify claims

- Track weight per order and percent recyclable to show progress

|

Metric |

Typical Impact |

|---|---|

|

Recycled content 50–70% |

Lower landfill waste; meet retailer goals |

|

DIM fee cut 15–30% |

Lower carrier charges per order |

|

On-demand printing 30–50% inventory cut |

Lower storage and obsolescence cost |

Simple visual: Box volume vs. DIM fee (ASCII graph)

This small chart shows how average box volume links to DIM fees. Each bar shows relative impact; lower volume cuts fees.

|

Box Volume (units) |

Visual Indicator |

DIM Fee Impact |

|---|---|---|

|

High |

███████████████ |

High fees |

|

Medium |

██████████ |

Medium fees |

|

Low |

████ |

Low fees |

Cut Packaging Costs in 2026 & Grow Your Brand

Ecommerce Packaging Trends 2026 will change costs and customer loyalty. Run a right-sizing pilot, test custom ecommerce boxes on a small SKU set, and measure DIM fees, returns, and NPS for 90 days. Use the model to pick the next 5 SKUs to scale. Act now to capture savings and delight customers under the Ecommerce Packaging Trends 2026 shift. Would you like a short audit checklist or a one-page cost model to start? Call Packings.

FAQs

How much can right-sizing save?

Right-sizing can reduce void fill by 40% and cut DIM fees by 15–30%. These savings lower shipping bills and carbon output per order. Track average box volume to measure gains.

What protects fragile items best?

Molded pulp and engineered paper cushions give strong protection while cutting plastic use by 50–70%. Test cushions on fragile SKUs and track damage rates for 90 days to confirm performance.

How do smart tags help?

Smart tags like QR codes and RFID cut lost items by 15–25% and lower claims by 10–20%. Use QR codes for small orders and RFID for pallets to get fast wins.

What are affordable custom ecommerce packaging options?

Options include on-demand printing, standard dielines, and modular inserts. These choices lower setup fees and let brands test looks with low minimums. Bulk runs still cut unit cost by 20–35%.